Professional ntse chaw tsim tshuaj paus ntawm thermal conductive cov ntaub ntawv

10+ Xyoo Kev Tsim Khoom

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-8600 Series Thermal Paste

★ Tej yam khoom ntawm JOJUN-8600 Series Thermal Paste

| Thermal conductiveMuab tshuaj txhuam | |||

| Khoom | Chav tsev | Khoom Series | Txoj Kev Xeem |

| YOG-8600 | |||

| Xim |

| Xiav | Pom kev |

| Qhov ntom | g/cc | 3.2 | ASTM D 792 Cov Lus Qhia Tshwj Xeeb |

| Extrusion Ceev30cc,90psi ua | g/min | 10-90 Nws |

|

| Daim ntawv thovKub | ℃ | -50 ~ + 200 |

|

| FlammabilityChav kawm |

| V0 | UL94 ua |

| KubKev coj ua | W/mK | 6 | ASTM D 5470 Cov Lus Qhia Tshwj Xeeb |

| Kev tawgQhov hluav taws xob | KV/mm | > 5 | ASTM D 149 Cov |

| NtimKev tiv thaiv | os cm | 10^13 | ASTM D 257 |

| DielectricTsis tu ncua | 1 MHz | 7 | ASTM D150 |

★ Daim ntawv thov

LED nti

Cov khoom siv sib txuas lus,

Mobile xov tooj CPU,

Nco module,

IGBT

Lub zog modules,

Lub zog semiconductor teb.

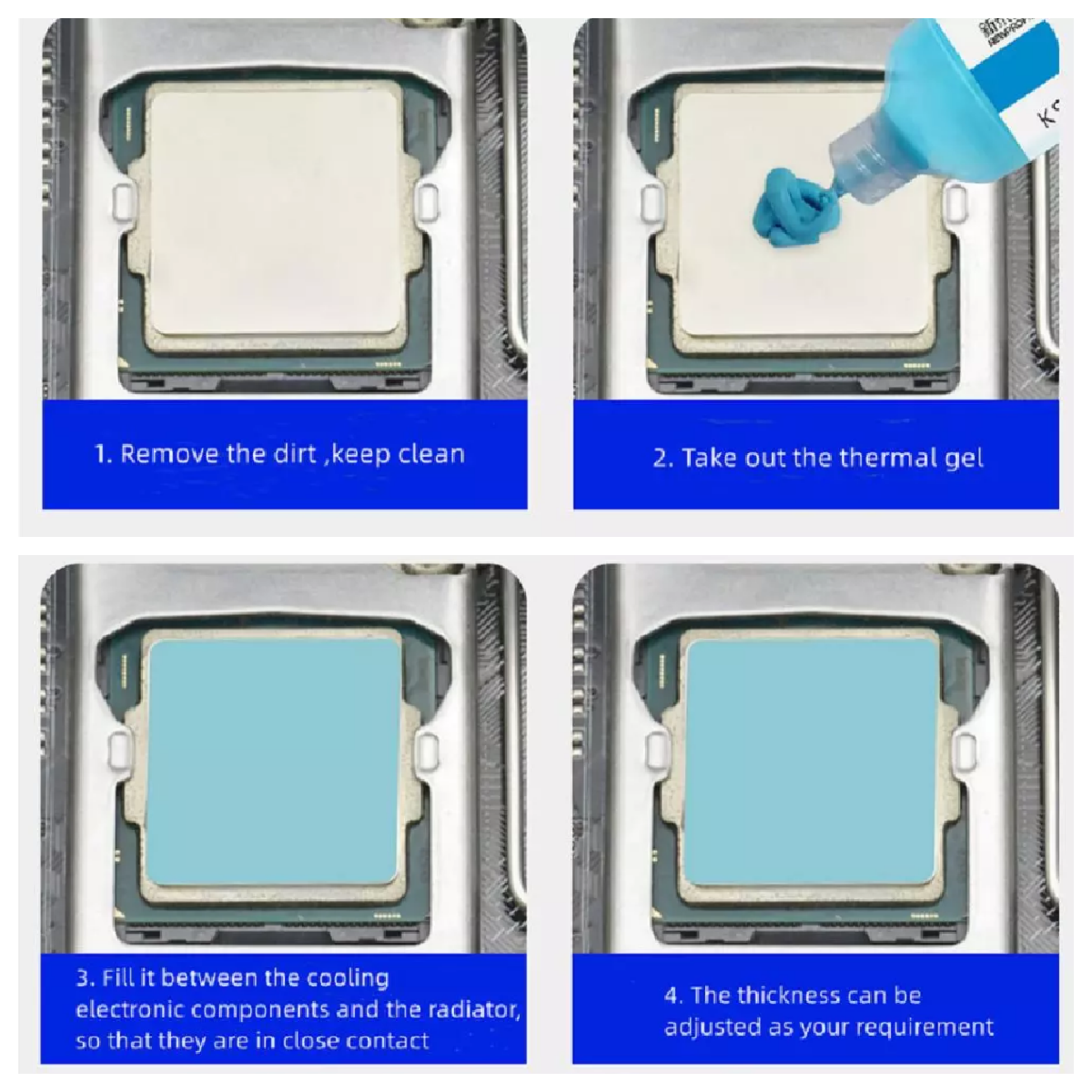

★ Kev siv

★ Cov txheej txheem ntau lawm

Sib tov

Extrusion

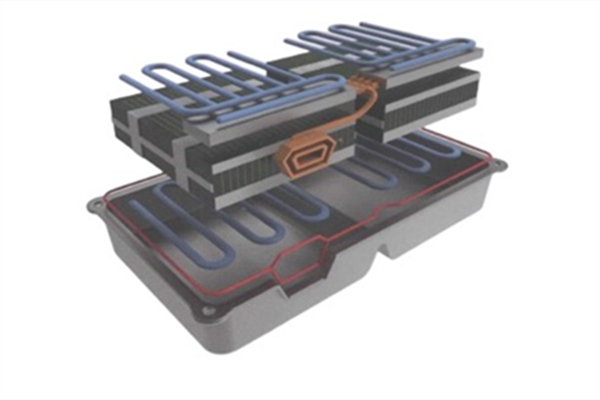

Thermal Pad Ntau lawm kab

Qoob loo

Pob

Cov khoom tawm

★ R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★ Nta thiab Cov txiaj ntsig

Piv nrog thermal ncoo, thermal muab tshuaj txhuam yog softer thiab muaj qhov zoo ntawm qhov chaw affinity.Nws tuaj yeem raug compressed mus rau ib qho tuab tuab heev, uas ua rau muaj txiaj ntsig zoo rau kev hloov pauv cua sov, thiab tuaj yeem compressed rau 0.1 hli ntawm qhov qis tshaj.Lub sijhawm no, thermal kuj tuaj yeem nyob ntawm 0.08℃·2/W rau 0.3℃·in2 / W, uas tuaj yeem ncav cuag qhov kev ua tau zoo ntawm ib feem ntawm cov roj silicone.Tsis tas li ntawd, thermalmuab tshuaj txhuamyuav luag tsis muaj hardness, tom qab siv cov khoom siv yuav tsis tsim kev ntxhov siab sab hauv.

Thermal paste yog yooj yim ua hauj lwm nrog dua thermal roj.Kev siv cov roj silicone feem ntau yog tshuaj ntsuam lossis steel phaj luam ntawv, lossis cov txhuam ncaj qha, tsis zoo rau cov neeg siv thiab ib puag ncig, thiab vim tias nws cov fluidity, feem ntau tsis tuaj yeem siv rau lub sijhawm tuab dua 0.2 hli.

Thiab cov thermal conductivity av nkos arbitrary molding rau hauv cov duab xav tau, rau qhov tsis sib xws PCB pawg thawj coj saib thiab cov khoom siv tsis tu ncua (xws li cov roj teeb, cov khoom ntawm lub kaum sab xis, thiab lwm yam), tuaj yeem ua kom muaj kev sib cuag zoo.Thermal gel muaj qee qhov adhesion, thiab yuav tsis muaj teeb meem ntawm cov roj thiab qhuav, muaj qee yam zoo hauv kev ntseeg tau.

★ Daim ntawv pov thawj

Nta ntawm Cov Khoom Siv Thermal

-

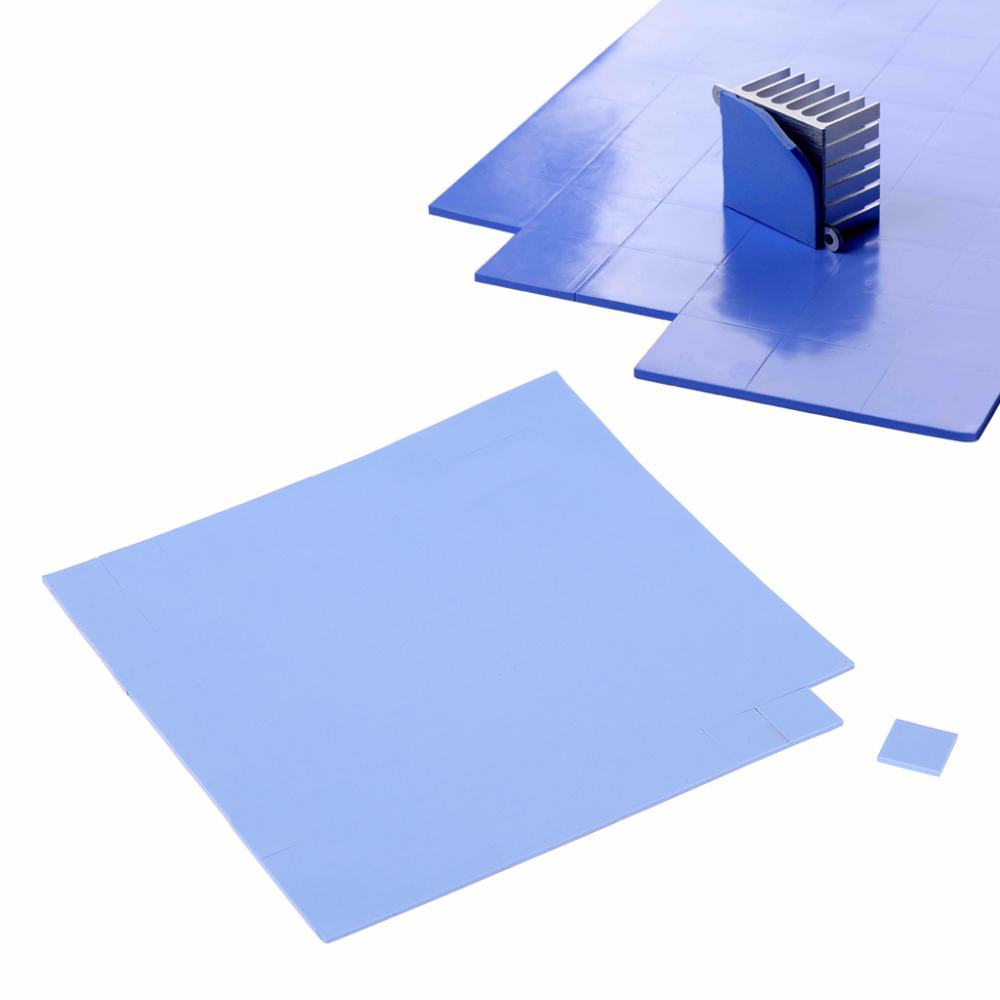

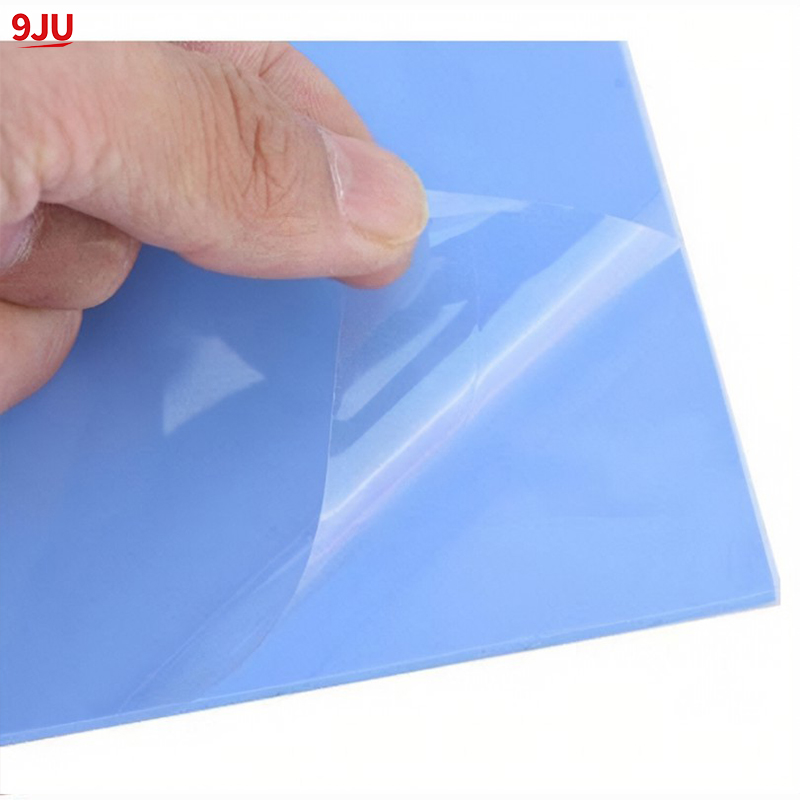

Cov yam ntxwv ntawm Thermal Pad

1. Zoo thermal conductivity: 1-15 W / mK.

2. Tsawg hardness: Lub hardness ranges ntawm Shoer00 10 ~ 80.

3. Hluav taws xob insulating.

4. Yooj yim rau kev sib dhos. -

Nta ntawm Thermal Paste

1. Ob feem dispensable gap filler, kua nplaum.

2. Thermal conductivity: 1.2 ~ 4.0 W / mK

3. High voltage rwb thaiv tsev, siab compression, zoo kub kuj.

4. Daim ntawv thov compression, tuaj yeem ua tiav cov haujlwm ua haujlwm. -

Cov yam ntxwv ntawm Thermal Grease

1. Tsawg roj sib cais (mus rau 0).

2. Hom ntev ntev, kev ntseeg tau zoo.

3. Muaj zog tiv thaiv huab cua (siab thiab kub tsis kam tiv taus -40 ~ 150 ℃).

4. Moisture resistance, ozone kuj, aging kuj.

1.jpg)