Professional ntse chaw tsim tshuaj paus ntawm thermal conductive cov ntaub ntawv

10+ Xyoo Kev Tsim Khoom

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-6100 Series Thermal Pad

★ Tej yam khoom ntawm JOJUN-6100 Series Thermal Pad

| Yam Khoom Ntawm JOJUN6100 | |||

| Khoom | Chav tsev | Khoom Series | Txoj Kev Xeem |

| YOG 6100 | |||

| Xim |

| Customized | Pom kev |

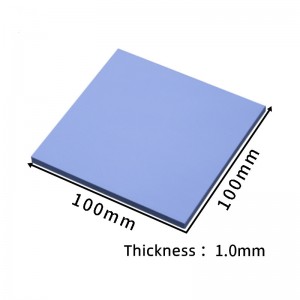

| Thickness | mm | 0.5-5 | ASTM D 374 3 |

| Tshwj xeebLub ntiajteb txawj nqus | g/cc | 2.8 | ASTM D 792 Cov Lus Qhia Tshwj Xeeb |

| Hardness | Ntug oo | 30-70 Nws | ASTM D 2240 Cov Lus Qhia |

| Daim ntawv thovKub | ℃ | -50 - +200 |

|

| FlammabilityChav kawm |

| V0 | UL94 ua |

| KubKev coj ua | W/mK | 1 | ASTM D 5470 Cov Lus Qhia Tshwj Xeeb |

| Kev tawgQhov hluav taws xob | KV/mm | > 6 | ASTM D 149 Cov |

| NtimKev tiv thaiv | os cm | 10^14 ib | ASTM D 257 |

| DielectricTsis tu ncua | 1 MHz | 7 | ASTM D150 |

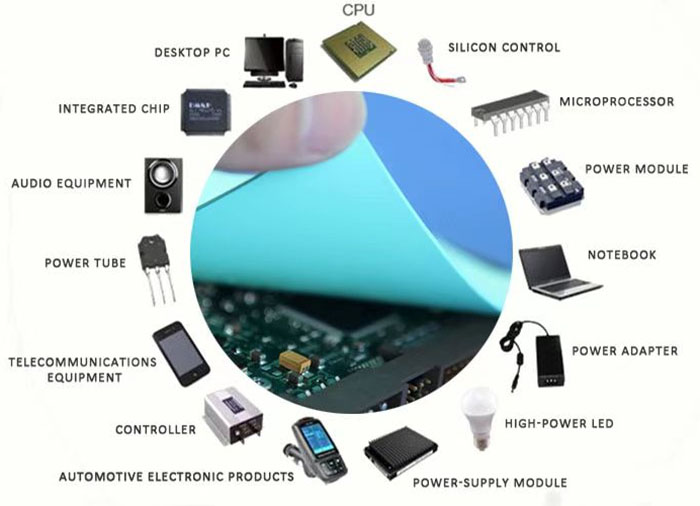

★ Daim ntawv thov

1. LED kev lag luam

Lub thermal conductive gasket yog siv nruab nrab ntawm aluminium substrate thiab lub dab dej kub.

Lub thermal conductive gasket yog siv nruab nrab ntawm aluminium substrate thiab lub plhaub.

2. Kev lag luam fais fab

Siv cov khoom siv hluav taws xob ntawm MOS raj, transformer (los yog capacitor / PFC inductor) thiab lub dab dej kub lossis vaj tsev.

3. Kev sib txuas lus kev lag luam

Thermal conduction thiab tshav kub dissipation ntawm lub main board IC thiab lub dab dej kub los yog plhaub.

Thaum tshav kub kub conduction thiab tshav kub dissipation ntawm lub teeb saum lub thawv DC-DC IC thiab lub plhaub.

4. Automotive Electronics Kev Lag Luam

Thermal conductive gaskets tuaj yeem siv rau hauv kev lag luam hauv tsheb hluav taws xob (xws li xenon teeb ballasts, stereos, tsheb series khoom, thiab lwm yam).

5. PDP/LED TV

Thaum tshav kub kub conduction ntawm lub hwj chim amplifier IC, duab decoder IC thiab lub dab dej kub (tsev).

★ Cov txheej txheem ntau lawm

Sib tov

Extrusion

Thermal Pad Ntau lawm kab

Qoob loo

Pob

Cov khoom tawm

★ R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

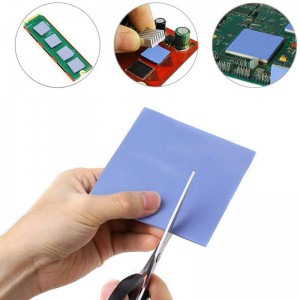

★ Nrov Science Paub

Thermal conductive gaskets yog siv los sau cov huab cua sib txawv ntawm cov khoom siv cua sov thiab lub dab dej kub lossis hlau puag.Lawv cov yam ntxwv hloov tau yooj yim thiab elastic ua rau lawv npog qhov tsis sib xws.Thaum tshav kub kub yog kis los ntawm cov khoom sib cais los yog tag nrho PCB mus rau lub plhaub hlau lossis diffusion phaj, uas tuaj yeem txhim kho kev ua haujlwm thiab kev pabcuam lub neej ntawm cov khoom siv hluav taws xob cua sov.Lub tshav kub conduction ncoo yog ntsia nruab nrab ntawm lub tshav kub dissipation txias phaj thiab cov cua sov nti kom xa cov cua sov los ntawm cov nti mus rau lub tshav kub dissipation txias phaj, yog li txo qhov kub ntawm lub nti.Lub compression kev nyuaj siab yuav tshwm sim thaum lub tshav kub conduction ncoo yog compressed.Lub compression kev nyuaj siab yuav nce nrog qhov nce ntawm compression npaum li cas.Thaum xaiv lub tshav kub conduction ncoo, xyuam xim hais tias lub compression kev nyuaj siab ntawm lub tshav kub conduction ncoo thaum lub sij hawm compression yuav tsum tsis txhob ntau tshaj qhov siab tshaj plaws yuav tsum tau ntawm lub cua sov nti, txwv tsis pub lub nti yuav puas.

★ Vim Li Cas Xaiv Peb?

1. Pab neeg R & D kws tshaj lij

Kev them nyiaj yug daim ntawv thov kev pab xyuas kom koj tsis txhob txhawj txog ntau yam cuab yeej xeem.

2. Cov khoom lag luam kev koom tes

Cov khoom raug muag rau ntau lub teb chaws thoob plaws ntiaj teb.

3. Kev tswj xyuas nruj

4. Lub sijhawm xa khoom ruaj khov thiab tsim nyog kev txiav txim lub sijhawm tswj.

Peb yog ib pab neeg tshaj lij, peb cov tswv cuab muaj ntau xyoo dhau los hauv kev lag luam thoob ntiaj teb.Peb yog ib pab neeg hluas, tag nrho ntawm kev tshoov siab thiab kev tsim kho tshiab.Peb yog ib pab neeg mob siab rau.Peb siv cov khoom tsim nyog los ua kom cov neeg siv khoom txaus siab thiab yeej lawv txoj kev ntseeg siab.Peb yog ib pab neeg nrog npau suav.Peb txoj kev npau suav ib txwm yog muab cov neeg siv khoom nrog cov khoom lag luam txhim khu kev qha thiab txhim kho ua ke.Cia siab rau peb, yeej-yeej.

★ Daim ntawv pov thawj

Nta ntawm Cov Khoom Siv Thermal

-

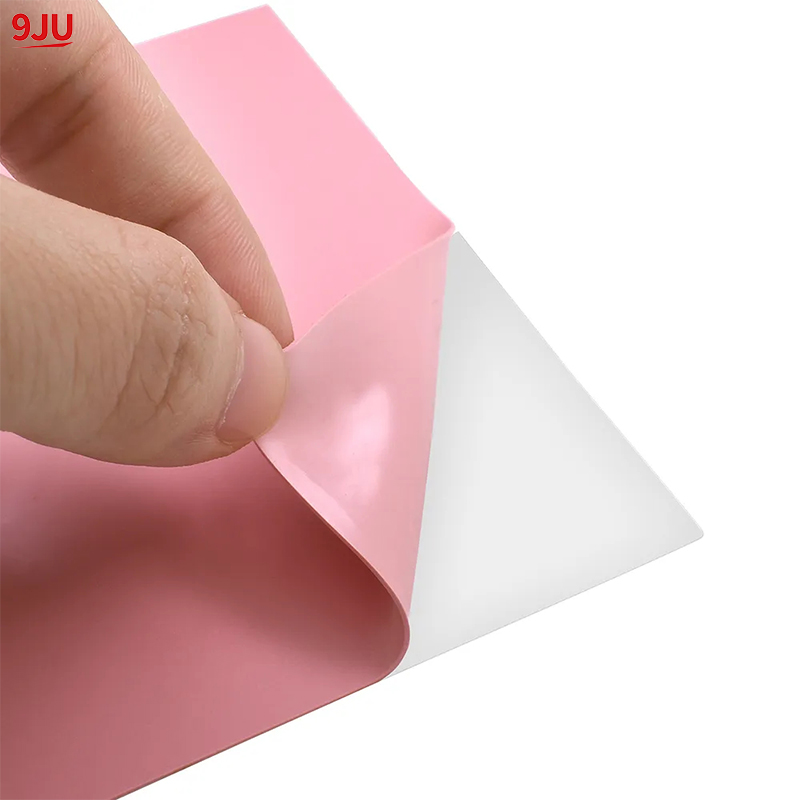

Cov yam ntxwv ntawm Thermal Pad

1. Zoo thermal conductivity: 1-15 W / mK.

2. Tsawg hardness: Lub hardness ranges ntawm Shoer00 10 ~ 80.

3. Hluav taws xob insulating.

4. Yooj yim rau kev sib dhos. -

Nta ntawm Thermal Paste

1. Ob feem dispensable gap filler, kua nplaum.

2. Thermal conductivity: 1.2 ~ 4.0 W / mK

3. High voltage rwb thaiv tsev, siab compression, zoo kub kuj.

4. Daim ntawv thov compression, tuaj yeem ua tiav cov haujlwm ua haujlwm. -

Cov yam ntxwv ntawm Thermal Grease

1. Tsawg roj sib cais (mus rau 0).

2. Hom ntev ntev, kev ntseeg tau zoo.

3. Muaj zog tiv thaiv huab cua (siab thiab kub tsis kam tiv taus -40 ~ 150 ℃).

4. Moisture resistance, ozone kuj, aging kuj.